PE-RT Type II pipe is made of quality materials that comply with rigid codes and standards in advanced countries. This eco-friendly pipe is toxic-free and corrosion-free even under the harsh operating environment such as high temperature and high pressure. PE-RE Type II comes in two different types – coil and tube. Easy and quick installation is another merit while minimizing fitting parts.

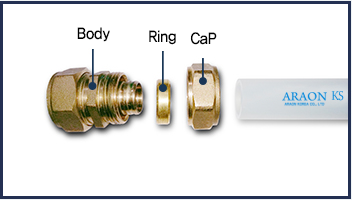

- The O-ring seal fitting method requires a fitting body, O-ring, cap.

- A pipe is tightened by connecting cap with fitting body.

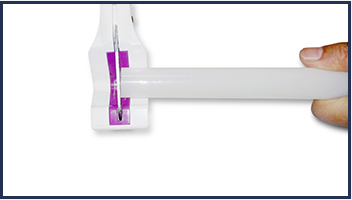

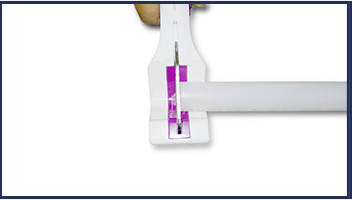

- The bend’s outside surface must be cut firstly.

- Use the dedicated pipe-cutter only.

- A pipe cutting work must be at 90-degree.

- Caution

A cutting chip and/or sawdust may result in crack and leakage. A pipe-cutting must be made at 90-degree, otherwise it may result in a crack in and between fitting elements, and thereby a fluid leakage.

- An assembly work must is made in sequence of cap, O-ring, and fitting body. No gap/crack is allowed.

- Caution

A fitting body must be fully inserted into a pipe, and then securely tightened against cut-surface.

- A cap is inserted into a fitting body.

- Caution

Do not apply excessive force when you fasten the cap.

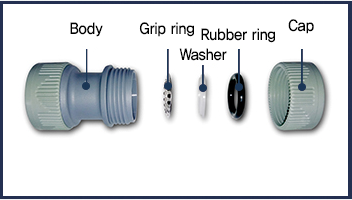

- The fitting elements include a fitting body, grip ring, washer, rubber ring, and cap.

- A grip ring keeps a pipe in right position, and a rubber ring creates a leak-proof seal.

- Caution

Do not re-use a fitting element; otherwise a damaged grip ring may result in water leakage.

- A pipe cutting work must be at 90 degree by using a dedicated pipe-cutter. Rotate the pipe while being cut.

- A pipe cutting work must be at 90-degree.

- Caution

A scratched or damaged fitting surface may result in water leakage. Keep the fitting elements away from abrasion and impurities

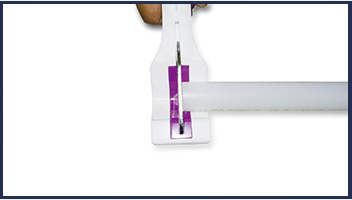

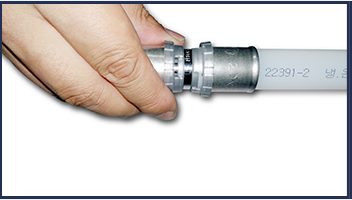

- Insert a suitable support sleeve into pipe after pipe-cutting work.

- To avoid disconnected pipe-fitting, a pipe fitting must be in a perfect circular, and a grip ring must be securely tightened.

- Caution

An absence of support sleeve may result in disconnected pipe fitting.

- Hold the pipe toward the open of fitting; and push & fit the pipe until it reaches end of fitting.

- A pipe must be inserted in two-stages. Do not forget to push & fit it again after a cap is completely tightened.

- Caution

Incomplete insertion (eg. up to O-ring) may result in disconnected pipe fitting.

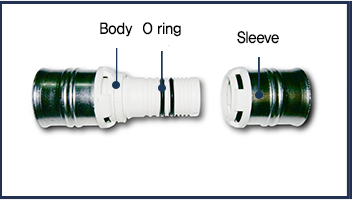

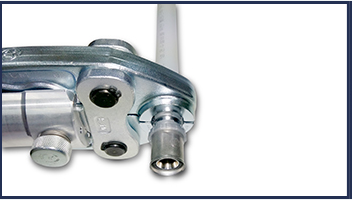

- The press-fit fitting method requires a fitting body, O-ring, and sleeve.

- A high pressure is used to deform the fitting and compress the sealant against the inner tubing, creating a leak-proof seal.

- The bend’s outside surface must be cut firstly.

- Use the dedicated pipe-cutter only.

- A pipe cutting work must be at 90-degree.

- Caution

A cutting chip and/or sawdust may result in crack and leakage. A pipe-cutting must be made at 90-degree, otherwise it may result in a crack in and between fitting elements, and thereby a fluid leakage.

- Insert suitable fitting elements into pipe after pipe-cutting work

- Caution

Make sure that the pipe should be inserted until it reaches the groove of sleeve coupling.

- A sleeve coupling is securely tightened by using a press-fit fitting machine

- Caution

After completing fitting work, a visual inspection must be carried out to check; whether the fitting is a perfect circle; and whether the groove is seen.